Rigaku

Over the years I have worked on many different diffractometer makes and models and I have always found Rigaku hardware to be hard working, robust and ‘fixable’. This has often come at the expense of aesthetic beauty but still looks are not everything.

So it was a great pleasure when Rigaku won the tender to supply the University of Liverpool, Transformative Extended Materials Research Programme Grant, with a new cutting edge diffractometer system.

The system selected was a Rigaku 007 HF microfocusing rotating anode with a Kappa goniometer and CCD detector AF10K (AKA AF12) and Saturn 724+, respectively.

General Operation and Installation

I also had the great please of assisting Rigaku with the installation and being primary contact for the machine during my contract at Liverpool. I worked with a range of Rigaku engineers over the three years and Thermal Exchange who built a bespoke chiller control system for that particular install. I will be setting up a webalbum with images from the install and routine “diffraction life” in due course. I have already setup a YouTube site where I filmed some of the less exceptional aspects of the software and hardware.

CrystalClear Variable Temperature

As part of the tender Rigaku were also to provide a new variable temperature software suit called CrystalClear Variable Temperature or CCVT for short. There were many long and late nights working with Houston, Texas, on the project particularly at the early stages where Colin Acheson was working on the software to hardware programming. The team of Russ Athay, Colin (with input from Jim Pflugrath) and myself progressed to produce a package to allow the Rigaku software to talk to the Oxford Cryosystems Cryostream 700+ (OC). The end result was a great package to fully automate data collections over the entire temperature range of the OC device with the ability to customise the data collection mode, counting times and other variables.

This collaborative project between Rigaku and Liverpool lead to some truly novel and exciting science, only some of which has been published to date1. The first paper although not the first novel result to come from CCVT also includes its first citation.1

Features of CCVT

- Control over experiment - data collection type per “run” of the experiment

- Control over temperature variance

- Control over ramp rate

- Automated experiment population

- Adjustable dwell timing

- Segregated data storage for each temperature point

- Real-time temperature plotting

- Unique data collection naming - storage allowing for temperature and run order stored within folder naming To name but a few.

Problems

Interestingly it was through the use of CCVT that we readily identified hardware issues with our OC Cryostream 700+ and the diagnostic output in the CCVT made this easily recognisable.

However when we needed more detailed information we discovered that the complexity of the Rigaku logging system also meant it was not particularly easy to come by. I therefore wrote a small program to interrogate the Rigaku logs across the entire VT experiment producing a “CryoPad” like log file and png plots.

Screenshots and Result

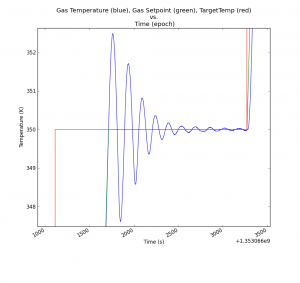

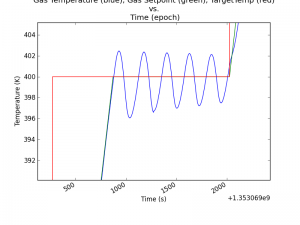

As you can see in the picture above the temperature profile is not as clean looking as you may expect from the OC 700+. By using ccvt2log we can analyse these results in more detail by extracting out the temperature and cryostream parameters from all 16 data collection runs. This instantly allows use to regenerate the plot above and using ccvt2log zoom in on a specific region.

For example we can examine the different temperature plateaus and look at the oscillations observed around the target temperature (red).

Rigaku at UMIST

It is almost impossible to compare the Rigaku I used at UMIST with machine at the University of Liverpool. It is like trying to compare a Ford model-T with a Tesla S. With that said I think I must include a picture of the old girl which we used to keep running ourselves using rubber bands and string. No we didn’t but we did need to keep a collection of ‘o-rings’ for the serial detector stops.

One thing I must point out is that the software this old, old, old machine used to use. The MSC TeXsan system even running on the old VAX machine was light years beyond its nearest competitors. Sadly this is one thing Rigaku has let slip over the years but I think they are trying to bring it back on track with CrystalClear 3.x onwards.